New stack plan for PEM electrolysers vows to reduce creation expenses

German specialists have developed bipolar plates for electrolyser cells without utilizing titanium, which they guarantee can additionally diminish the expense of harmless to the ecosystem hydrogen.

A gathering of specialists in Germany has proposed supplanting titanium (Ti) bipolar plates (BPPs) in proton trade film (PEM) water electrolysers with plates in view of covered hardened steel (ss) with an end goal to decrease ebb and flow high assembling costs. “PEM electrolysers right now utilize costly materials, for example, titanium and platinum bunch metals (PGMs), because of the brutal oxidation conditions inside the cells,” noticed the researchers, who guided out that BPPs represent up toward 60% of the battery costs.

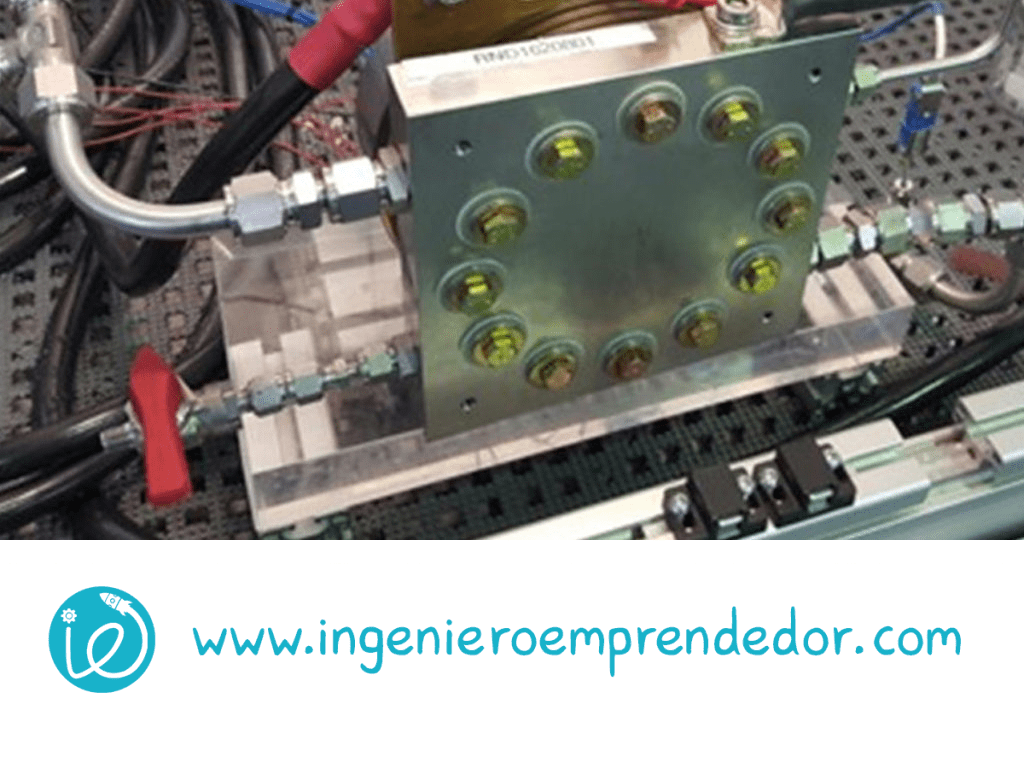

They utilized round formed plates with a functioning area of 86 cm2 given by Norwegian hydrogen expert Nel Hydrogen and covered them with treated steel and niobium (Nb) by vacuum plasma faltering (VPS). “Prior to beginning the faltering method, the substrates were sandblasted with silicon dioxide (SiO2) powder to expand the surface harshness as well as the bond of the covering powders, and preheated to 250 C in the vacuum chamber,” they made sense of. “The Nb layers were stored by applying a force of 1.0 kW for 15 min, so a layer thickness of 1.4 μm was accomplished, which was fixed by the previously mentioned fine fixing process.”

The battery was collected in a four-cell setup with various BPP anodes and worked on a test seat utilized for standard PEM electrolysers. During the 14,000-hour test, the phones with covered ss-BPP showed a presentation of around 1.9 V at 1 A cm-2, which the researchers portrayed as like that of a business reference cell. “The test convention incorporated no pre-arranged closure periods, however these occasions happened due to normal test station issues and normal difficulties experienced while working test seats for so long,” they indicated.

The exhibition of the Nb/ss-BPP plate was contrasted and that of an indistinguishable plate coordinating Ti, and the two coatings gave no indications of erosion and had the option to safeguard the substrate during activity completely. As per the researchers, the two plates performed equivalently to the Nel Hydrogen reference material and their presentation arrived at a cell proficiency of very nearly 78%, with a debasement pace of just 1.2 percent. “In any case, according to an expense perspective, the Nb covering offers a reasonable benefit over the Nb/Ti covering, as it requires two handling moves toward apply it and structure a thick and stable oxide layer,” they pushed.

The researchers depicted the stack plan in the paper ‘Long haul Operation of Nb-Coated Stainless Steel Bipolar Plates for Proton Exchange Membrane Water Electrolyzers’, distributed in Advanced Energy and Sustainability Research. “The outcomes got may stamp a defining moment for future electrolysis research, in which steel-based stack parts are viewed as the new norm, establishing the groundwork for monstrous expense decreases in PEM electrolysers and hence a fundamental variable for serious green hydrogen creation.”

The exploration bunch comprises of scholastics from the German Aerospace Center (DLR), the Esslingen University of Applied Sciences, the examination place Forschungszentrum Jülich GmbH and Nel Hydrogen itself.